Research and development

Contact data

"Quality is a way of thinking that makes us

apply and constantly look for the best solutions"

~ E. Deming

EKOPLON has been offering customers high-quality fertilizers and animal nutrition for 30 years, achieving the position of a valued manufacturer and supplier. In creating our products, we follow the basic assumption and goal - our products must effectively meet our customers' needs and expectations, increase the economic efficiency of their production in breeding and growing plants. In our activities, we are guided by the need to care for the development of our customers' business.

We combine science with the practice of creating close relationships with a wide range of farms, breeders and research centers.

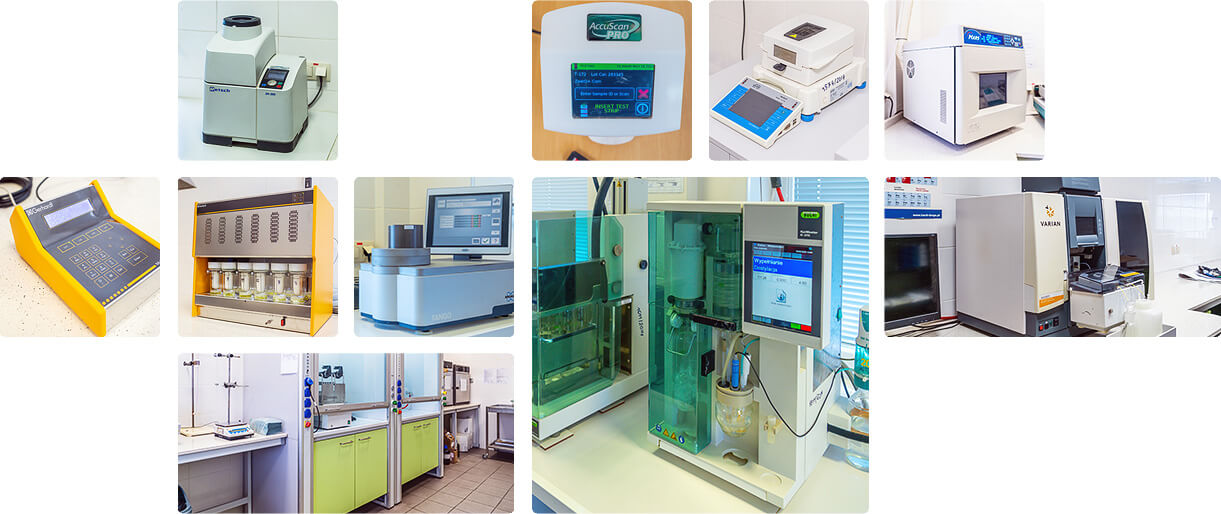

To optimize the recipes, our products are subject to thorough testing at every stage of production. Our experts use a modern laboratory, where fertilizers and animal nutrition are being tested. The results are consistently translated to production, constantly improving its quality.

Our final products and the raw materials used in production are completely safe and of the highest standards in force in the European Union.

GMP+ B1 – the GMP+ certificate ensures the safety and confirms that the compound feeds and premixes produced, stored and transported do not pose any risk to animals and people. GMP+ B1 implemented since 2017.

QS - the QS Certification System is a food and feed safety assurance system. It ensures control at every stage of the production process, starting from the farm, through feed producers, livestock breeders, slaughterhouses, butchers, to the final product that the consumer finds on the store shelf. The QS sysem can also cover the production of fruit and vegetables or retail food sales.

We are visible in the QS-ID database 4953113170556

Our laboratories participate in interlaboratory proficiency tests, the purpose of which is to assess the quality of the analysis results obtained.

Thanks to this, we are sure that the results of our analyzes meet the highest standards of reliability.

Permanent positioning of test results remains invariably of high quality, which confirms the proper functional quality of lab equipment and apparatus, high skills of lab workers and the high standard of the adopted research procedures.

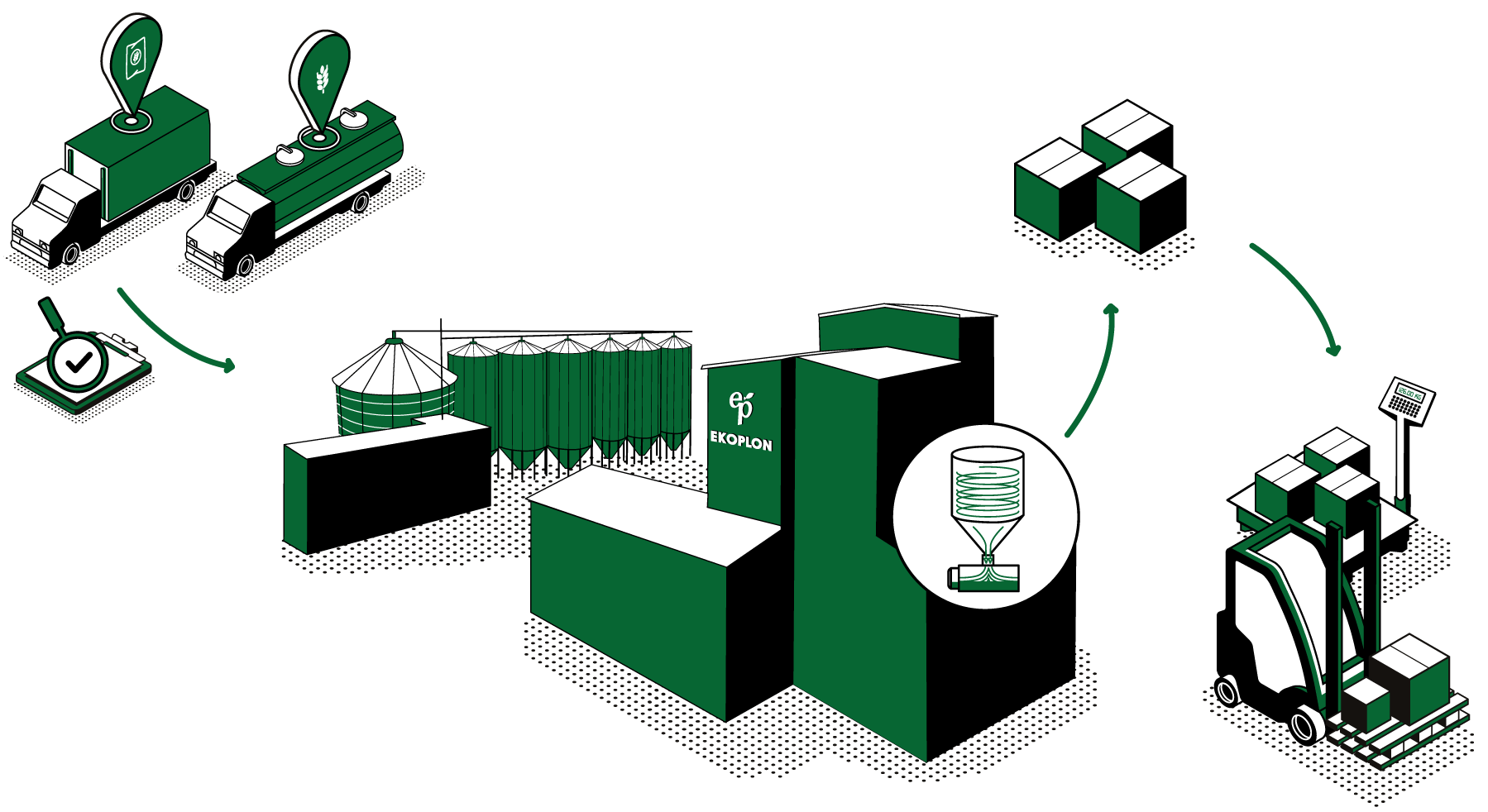

Stages of the production process in EKOPLON production plants

Continuous modernization of our production processes allows us to constantly increase the company's production capacity and constantly improve the quality of our products.

Thanks to investments in cutting-edge equipment and technology, we can provide our customers with a product of stable, repeatable and highest expected quality.

01Supply of raw materials from reliable suppliers. We make sure that the raw materials are always of the same, highest quality; therefore, each supply of raw materials undergoes quality control.

02Raw materials tested and meeting our standards are released to the plant and unloaded. Raw materials delivered in bulk to storage silos or unloading of bagged raw materials in a high-bay raw material warehouse.

03Commencing the production of a specific product starts with weighing the raw materials, then grinding and mixing them. The next stages of production are the granulation process, vacuum oiling and spraying enzymes onto the granules. Production is carried out under strict quality control performed at several production stages by highly qualified employees.

04Directly at the production site, all our products are packed in hygienic and sterile individual packages, or placed in dispatch tanks.

05Products from the final production stage, packed on pallets, go to the high-bay warehouse or to the shipping tanks, from where they go directly to our customers. Technologies used in EKOPLON fertilizers.

Technologies used in EKOPLON fertilizers

The production technologies of EKOPLON fertilizers are based on many years of experience and proven principles. Before they are introduced to the market, all fertilizers we make undergo a series of physicochemical tests and field experiments. Each stage of production takes place under the strict control of our technologists. Thanks to this, we provide only proven and wholesome products. The high quality of EKOPLON products is our priority. The delivery of each raw material is considered separately since the selection of appropriate raw materials has a major impact on the final quality of the fertilizers we make. Raw materials must meet high standards. We never use half measures. We only use raw materials of the highest quality and purity for production, which are fully compliant with our requirements.

We make every effort to ensure that our crystalline fertilizers meet customer expectations. Production takes place in stages. The micro- and macronutrient ingredients are weighed separately to eliminate the risk of error. Both stages are checked by Technologists and the Quality Control Department. The raw materials are then transported to the mixer. The mixing time is strictly defined by Technologists, which guarantees to obtain the appropriate homogeneity of the final product.

The manufacture of liquid fertilizers is a multi-stage process. The process of weighing raw materials and mixing is carried out under strict control according to appropriately developed recipes. Before being allowed for packaging, each batch of fertilizer is tested for its physicochemical and organoleptic parameters. All this so that only fully valuable fertilizers reach the market.

MAXIMUS Platinum fertilizers have been enriched with MPC² (Micro Protection Complex), which stimulates proper growth and better utilization of soil nutrients and prevents nutrient deficiencies.

Technology is based on lignosulfonates, which are a derivative of lignin, which, as an integral component of the plant cell walls, naturally enters all woody plants and serves as reinforcement. Made in the process of wood delignification and are present in the form of a brown, well-soluble powder.

.

.

CHELACID is a complex of microelements chelated with EDTA and organic acids. It ensures fast and safe micronutrient absorption into leaf cells, making foliar fertilization the best and fastest way to replenish micronutrients. It strengthens the plant's resistance to diseases, pests and physiological stress, and facilitates the combined use of fertilizers with multiple protection measures.

ComplexActive - ComplexActive are three biologically active substances whose task is to reduce the impact of abiotic stresses on the growth, development and functioning of crops. EKOLIST fertilizers contain ComplexActive, thanks to which they are a great solution for use both during optimal growth conditions and in periods when the conditions are not entirely favourable.